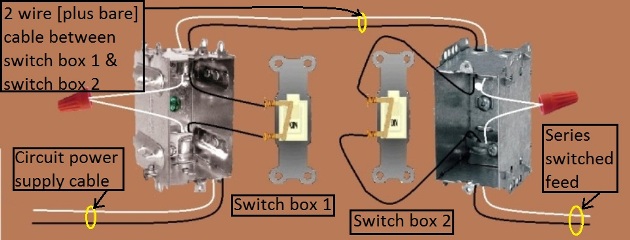

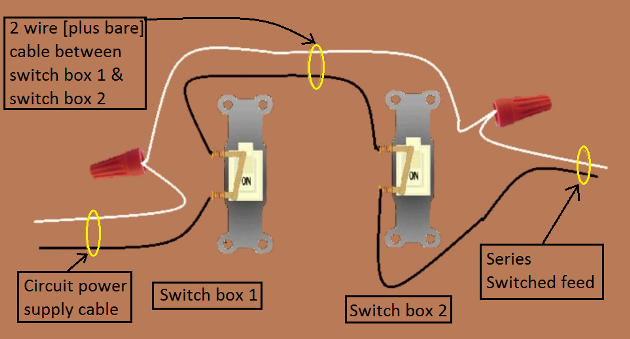

Series Switch Wiring

Power Source and Switched Feed at Different Switch

WHILE EXTREME CARE HAS BEEN IMPLEMENTED IN THE PREPARATION OF THIS SELF-HELP DOCUMENT, THE AUTHOR AND/OR PROVIDERS OF THIS DOCUMENT ASSUMES NO RESPONSIBILITY FOR ERRORS OR OMISSIONS, NOR IS ANY LIABILITY ASSUMED FROM THE USE OF THE INFORMATION, CONTAINED IN THIS DOCUMENT, BY THE AUTHOR and / OR PROVIDER.

Please read the notes on the ‘Series Switch Wiring’ selection page regarding the use of switches wired in series.

You will need…

- A 2 wire cable that is routed between switch box 1 and the switch 2 box – this wire cable comes with a black / white wire plus the bare equipment grounding wire.

- A 2 wire cable that is routed between switch box 2 and the switched item – this wire cable comes with a black / white wire plus the bare equipment grounding wire.

- A circuit power supply source wire cable that is routed to switch 1.

- Insulated wire nuts to connect / join wire together, variety of sizes out there so make sure you obtain the correct size.

- Wire staples, to affix the wire cables to wall studs as needed. Wire cable must be secured within 6 inches of entering the electrical box.

- Wire cable / wire strippers.

- Screwdrivers as required.

Holes drilled to feed wires through studs must be 1 1/4″ from edge of stud, in instances where the wire cable is closer then the edge of stud must have a 1/16-in. thick protective metal plate over the area where the cable is being feed through (may want to notch the stud so that that the protective plate does not create a bump on the drywall). Also read the article called ‘Wire Routing Basics’

Wire cables entering the electrical box – secure the cable clamp at the box snug enough that the cable cannot come out but not too tight as to pinch the cable and break through the insulated cover of the cable.

You must have at least 6 inch length of wire inside the electrical box, it can be a bit more but not less, it can fail an inspection if the length of each wire is less than 6 inches. Also read the article called ‘Box Fill Calculations‘ as there is a limit on how many wires are allowed for a certain size electrical box.

STEP 1 – Make certain that the power supply cable is dead – turn off the electrical breaker at the service panel. Make certain that everyone in the house is aware of what you are doing so that they do not get the notion to reset the breaker when another light in the home is not working.

STEP 2 – Make the box openings (if a existing home)

STEP 3 – Feed / Route the wire cables.

STEP 4 -Mount / Install the Electrical Boxes (make sure the electrical boxes are secured as some fixtures are heavy and may require additional support) [The electrical box should not extend beyond the edge of the finished wall or ceiling so that the fixture can mount flush to the ceiling and the wall switch cover will mount flush – but it also should not be recessed too far into the wall or ceiling]; then feed the wire cables into the electrical boxes. Sometimes because of tight openings in existing homes, the wire cable may to be feed into the electrical box then the box put in position and secured.

STEP 5 – Connect the wires…

Connections Instructions:

(as depicted in the diagrams above)

At the Switched item box (such as a furnace)…

One cables entering this box.

- a) Connect to the black wire to the switched ungrounded conductor connection (hot) of the switched item (such as a furnace).

- b) Connect the white wire to the grounded conductor connection (neutral) of the switched item (such as a furnace).

- c) please see under important notes in regards to the equipment grounding conductor (bare wire).

At switch 1 box…

Two cables entering this box, one from the ‘circuit power supply cable’ and one coming from switch 2.

- a) using an insulated wire nut connect/ join the white wire coming from ‘circuit power supply cable’ + the white wire coming from switch 2.

- b) connect the black wire coming from ‘circuit power supply cable’ to one of the main screws of switch 1.

- c) connect the black wire coming from switch 2 to the remaining main screw of switch 1.

- d) please see under important notes in regards to the equipment grounding conductor (bare wire).

At switch 2 box…

Two cables entering this box, one coming from switch 1 and one coming from switched item.

- a) using an insulated wire nut connect / join the white wire coming from switch 1 + the white wire coming from switched item.

- b) connect the black wire coming switch 1 to one of the main screw of switch 2.

- c) connect the black wire coming from ‘switched item’ to the other main screw of switch 2.

- d) please see under important notes in regards to the equipment grounding conductor (bare wire).

Important Notes:

By electrical codes you MUST have at least 6 inches of wire in the electrical box itself, and also the wire must be able to reach at least 3 inches outside the box, it can fail an electrical inspection if the required min. wire length is not met. You may have the wires a bit longer (within reason) but they cannot be shorter. Also see the note on box fill further down in this article.

You are allowed to re-designate a white wire to be used as a hot (ungrounded conductor) in switch circuits but in those cases where a white wire is used in this manner, you must wrap a piece of black electrical tape around that white wire inside the box to signify that is being used as an ungrounded (hot) conductor.

You cannot re-designate a white wire that is actually connected to a light fixture / switched item itself.

In the configuration depicted on this page, all white wires are grounded conductors (neutrals) and therefore is left as white with NO black tape on it.

Please refer to your switched item documentation for connections there, you may post to our forums for additional help for this.

What is not shown in the drawings to avoid confusion, is that each wire cable also has a bare equipment grounding wire included. This wire is connected to a grounding screw in each electrical box (if the box is metal), joined either through the grounding screws in the box itself or via a wire nut to the bare wire of the next cable entering / exiting the box, it is also connected to any grounding screw (if there is one) on the switch itself, as well as any grounding screw at the switched item (green wires are grounds). Now if using a plastic box, it is made of a material that is non conductive, however some plastic boxes have a metal strip inside that can still be used to connect equipment grounding wires, in the event that it does not use wire nuts to join the bare grounding wires together. The equipment grounding wire (bare in most cables) must be electrical conductively joined throughout the circuit. Green wires are also equipment grounding conductors.

If there is an equipment grounding screw on the switch it may be green in color and be separated away from the main connections of the switch and likely part of the metal frame that is also part of the mounting structure of the switch.

Foreign Users:

The colors of the wires depicted are based on the standards and code requirements / configuration in the United States and Canada. If you are viewing this site from a foreign country, your wiring standards and color of wires may be different but the principal and sequence of wiring will still remain the same. Therefore the information in this article may still be of use to you regardless of what country you may be in. Just translate the colors used here to the color of wires used in your country in regards to ungrounded (hot) conductors / grounded conductors (neutral) and equipment grounding conductors as well know applicable code requirements in your country.

By: Donald Kerr