Convert Pull String to Wall Switch

2011 NEC Compliant

(2011 NEC new rule 404.2 (C) Compliant)

For more information on this new rule read

‘2011 NEC New Rule ‘Switch Connections’

Home builders often install pull string lighting in unfinished basements, when you do get around to start finishing the basement you will likely want to convert those pull string lights to be controlled by a wall switch. Sometimes though you may even want to relocate those lights. If you need to relocate you may have to run a new wire cable if the existing cables are too short. This article is addressing the wiring changes to convert to a wall switch.

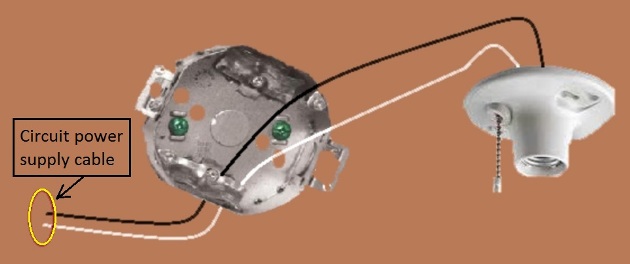

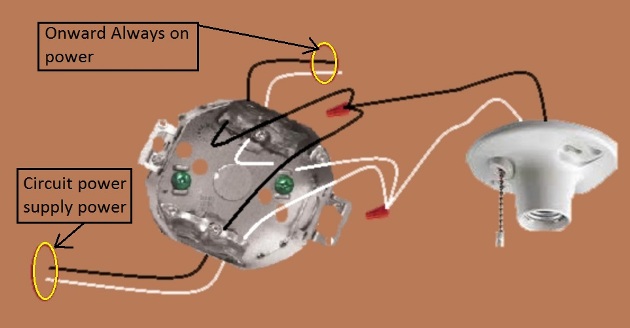

Before conversion you will likely either have one of the following two configurations, the first picture is a single pull string fixture with no onward power, the 2nd is a pull string fixture with onward power.

a) no onward power

b) with onward power

Conversion options…

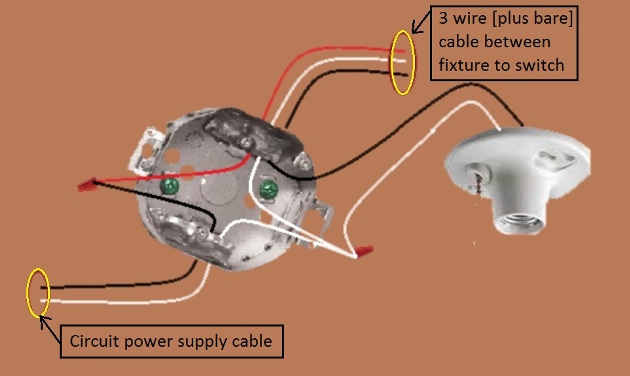

If there is no onward power as in the 1st picture (a) above.

Connections Instructions:

(as depicted in the diagram above, describing only the wires that require changes)

At the Fixture box…

Run a new 3 wire (plus bare) cable between fixture and switch.

- a) disconnect the black wire from fixture, using a insulated wire nut connect / join the black wire of the ‘circuit power supply cable’ + the red wire going to switch.

- b) connect the black wire coming from switch to the switched ungrounded conductor (hot) of fixture – if the fixture has screw type connections then connect to the brass color screw.

- c) using an insulated wire nut connect / join the white wire coming from switch + the white wire from ‘circuit power supply cable’ + the grounded conductor (neutral) of fixture – if the fixture has screw type connections then connect to the silver color screw.

- d) please see under important notes in regards to the equipment grounding conductor (bare wire).

Now refer to the articles on basic switch, 3 way switch & 4 way switch, choose any appropriate option with ‘NEC 2011 compliant) circuit ‘power at fixture’. Pick up on the wiring on the switch portion of those circuits with the cable going between fixture and switch.

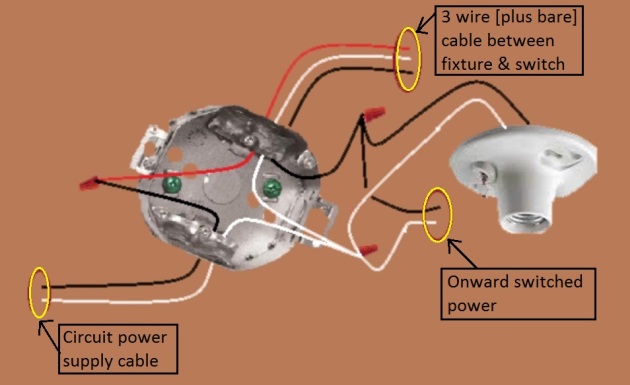

If there is onward power as in the 2nd picture (b) above.

Now is the onward cable going to another pull string fixture, if so you do have the option of having the same switch also switch the fixture attached to the onward cable, but if you decide to do that make certain that the onward cable does not eventually feed any outlets or fixtures that you do not want switched by the same switches.

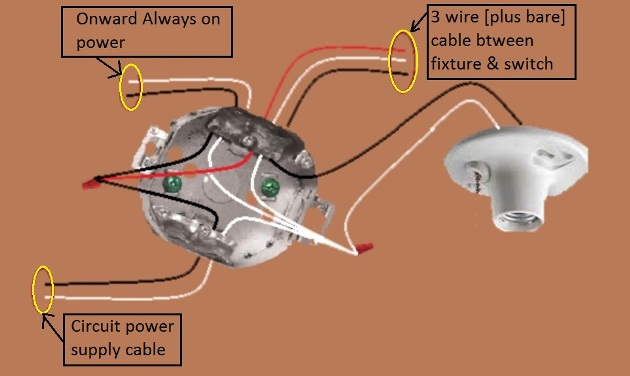

2a) convert but have onward cable with always on power.

Connections Instructions:

(as depicted in the diagram above, describing only the wires that require changes)

Run a new cable between fixture and switch (3 wire plus bare).

- a) disconnect the black wire from fixture, using a insulated wire nut connect / join the black wire of the ‘circuit power supply cable’ + the red wire going to switch + black wire of ‘always on’ onward cable

- b) connect the black wire coming from switch to the switched ungrounded conductor (hot) of fixture – if the fixture has screw type connections then connect to the brass color screw.

- c) using an insulated wire nut connect / join the white wire coming from switch + the white wire from ‘circuit power supply cable’ + the grounded conductor (neutral) of fixture – if the fixture has screw type connections then connect to the silver color screw. + the white wire on onward cable

- d) please see under important notes in regards to the equipment grounding conductor (bare wire).

Now refer to the articles on basic switch, 3 way switch & 4 way switch, choose any appropriate option with ‘(NEC 2011 compliant) circuit power at fixture’. Pick up on the wiring on the switch portion of those circuits with the cable going between fixture and switch.

2b) covert but have onward cable also switched.

Connections Instructions:

(as depicted in the diagram above, describing only the wires that require changes)

Run a new cable between fixture and switch (3 wire plus bare).

- a) disconnect the black wire from fixture, using a insulated wire nut connect / join the black wire of the circuit power supply cable + the red wire coming from switch.

- b) using a insulated wire nut connect / join the black wire coming from switch + black wire of onward cable + the black wire going to the switched ungrounded conductor (hot) of fixture – if the fixture has screw type connections then connect to the brass color screw.

** c) using an insulated wire nut connect / join the white wire coming from switch + white wire of onward cable + the white wire from ‘circuit power supply cable’ + the grounded conductor (neutral) of fixture – if the fixture has screw type connections then connect to the silver color screw. - d) please see under important notes in regards to the equipment grounding conductor (bare wire).

Please Note that all items connected to the onward cable will be switched even outlets down the line, for example the original wiring may have several pull string fixtures and an outlet after the last fixture, so confirm what is down stream after the existing pull string fixture you wish to convert before deciding on rather to have switched power on the onward cable.

Now refer to the articles on basic switch, 3 way switch & 4 way switch, choose any appropriate option with ‘(NEC 2011 compliant) circuit power at fixture’. Pick up on the wiring on the switch portion of those circuits with the cable going between fixture and switch.

Important Notes:

By electrical codes you MUST have at least 6 inches of wire in the electrical box itself, and also the wire must be able to reach at least 3 inches outside the box, it can fail an electrical inspection if the required min. wire length is not met. You may have the wires a bit longer (within reason) but they cannot be shorter. Also see the note on box fill further down in this article.

If the fixture has screw type connectors, the ungrounded conductor (hot) is connected to the brass color screw, and the grounded conductor (neutral) is connected to the silver color screw. If it has black and white wires coming from fixture, then just connect black to black and white to white. Use wire nuts of the correct size to join wires together.

What is not shown in the drawings to avoid confusion, is that each wire cable also has a bare equipment grounding wire included. This wire is connected to a grounding screw in each electrical box (if the box is metal), joined either through the grounding screws in the box itself or via a wire nut to the bare wire of the next cable entering / exiting the box, it is also connected to any grounding screw at the fixture (green wires that attach to the fixture are grounds). Now if using a plastic box, it is made of a material that is non conductive, however some plastic boxes have a metal strip inside that can still be used to connect equipment grounding wires, in the event that it does not use wire nuts to join the bare grounding wires together. The equipment grounding wire (bare in most cables) must be electrical conductively joined throughout the circuit. Green wires are also equipment grounding conductors.

Please read all the notes in the articles for the switch portion.

Be Aware that there is a limit by code on how many wires can be in a given size electrical box, when adding more wires to the same box you may have to install a larger and / or deeper box to allow space for more wires coming and out of the box.

Here is an article / explanation in regards to box fill calculations ‘Box Fill Calculation’

Foreign Users:

The colors of the wires depicted are based on the standards and code requirements / configuration in the United States and Canada. If you are viewing this site from a foreign country, your wiring standards and color of wires may be different but the principal and sequence of wiring will still remain the same. Therefore the information in this article may still be of use to you regardless of what country you may be in. Just translate the colors used here to the color of wires used in your country in regards to ungrounded (hot) conductors / grounded conductors (neutral) and equipment grounding conductors as well know applicable code requirements in your country.

WHILE EXTREME CARE HAS BEEN IMPLEMENTED IN THE PREPARATION OF THIS SELF-HELP DOCUMENT, THE AUTHOR AND/OR PROVIDERS OF THIS DOCUMENT ASSUMES NO RESPONSIBILITY FOR ERRORS OR OMISSIONS, NOR IS ANY LIABILITY ASSUMED FROM THE USE OF THE INFORMATION, CONTAINED IN THIS DOCUMENT, BY THE AUTHOR and / OR PROVIDER.

By: Donald Kerr